The drill you know today has been around for a lot longer than you think, at least the idea of it. Electricity may not have been around when the first drill was being used but human ingenuity was and ancient Egyptians weren’t short of it.

The bore drill was the first to be used in 3000 B.C. which was followed by the auger drill which came about in Roman times. The electric drill most people know of came about in 1889. Invented by two Aussies, William Brian and Arthur Arnot. Thanks to their efforts in the mining industry we have the modern drill which is largely based on the one used in the 19th century.

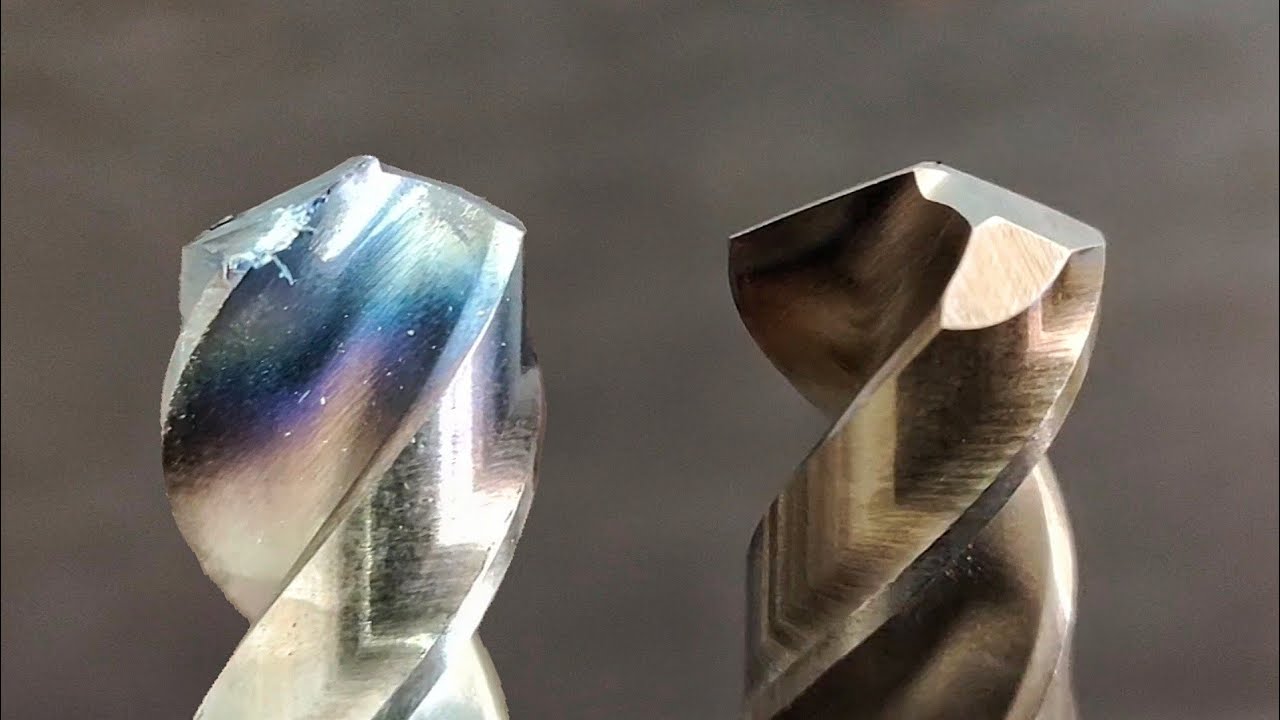

Benefits of HSS Bits

Wear

HSS or high speed steel drill bits are the embodiment of bits that can take a beating without getting worn out as much. You can use them for as long as you want and you’ll still be left with a capable high speed steel drill bit. They just don’t wear out that easily. This transcends into other aspects too.

Temperature

When it comes to high temperatures, know that HSS bits are able of withstand extremely high levels especially when you’ve used them for a long time. It’s not that they won’t get that hot, they just won’t experience any performance issues. Your drill will overheat before the bit does.

Performance

With their sharp design and extremely capable heat-resistant properties, HSS drill bits are able to deliver the best drilling performance you’ll find on a reasonably priced bit. While you won’t get blown away by it no matter the circumstances, an HSS bit will deliver what it’s made for.

Speed

If you want to drill many holes quickly, an HSS bit is almost always the answer. The speed at which you can drill through materials is astounding for a bit that doesn’t cost a fortune or require special treatment in order to stay sharp.

Versatile

You can use HSS bits on any material as long as you’re using the right one and there are plenty to choose from which makes them a great solution for almost every occasion.

Types of HSS Bits

Tungsten

When you need a more dynamic HSS bit you should consider going for a tungsten drill bit which has enhanced wear resistance as well as temperature resistance and hardness. There are two types of tungsten bits known as Type T and Type M with the former being made of 20% tungsten and the latter using only 1.25% tungsten. Alongside tungsten, there’s chromium, molybdenum, carbon and vanadium.

Cobalt

With a cobalt high speed steel drill bit, you get a piece of steel classed as M42. This means that the steel these bits are made has about 8% cobalt. This helps with both heat resistance and red hardness while it decreases the cycle times. Cobalt HSS bits are far more affordable than tungsten but they are not nearly as capable when it comes to strength and overall resilience.

CPM REX M4

Steel is still at the core of CPM REX M4 HSS bits but it’s accompanied by vanadium, manganese, chromium, silicon, molybdenum and tungsten. Modified thanks to extreme heat, CPM REX M4 HSS bits are the most capable of the three in terms of hardness, heat and wear resistance as well as reducing downtime between cycles.

What to Consider

Length

A good rule of thumb when it comes to choosing the right length drill bit for the job is to go with the shortest one you can have for your project. That’s mainly because a shorter HSS bit is much more accurate and gives you better control than a longer one ever will. Also, shorter HSS drill bits are more rigid and thus you’re able to use one more often and for longer. But if the task at hand requires you to use a longer bit then you definitely should, but not longer than what’s needed.

Diameter

Measured in millimetres, the bit’s diameter is determined by the size of the holes you want to make. There’s no right or wrong here as long as you’re using the right size bit for the holes you need to make. Drill bit diameters range from as little as 1mm and go up to 10mm. If unsure, go for a set of different diameter bits so that you can take on a higher number of projects and not feel limited.

Shank

The type of shank or part that goes into the drill which is essentially the base of the bit, matters as much as its dimensions and the material it’s made of. For instance, a straight shank, being the most common, is a circular shank that has the same size both up and down therefore it fits best in a three-jaw chuck. Hex shanks, on the other hand, have six sides which makes them best for high-torque applications.